Turning waste into value: brine valorisation.

What if brine wasn’t waste? Brine isn’t the problem, it’s the missed opportunity. What every water leader should know about this.

We recently brought to the table a critical and often overlooked topic: brine valorisation.

Following the success of our LinkedIn article, which reached over 6,000 professionals worldwide, we take this discussion even deeper.

The world is shifting.

After decades of globalization and interdependence, largely shaped by the availability of natural resources, we’re now seeing a rising demand for sustainability and circular economy principles.

Like it or not, the logic is simple:

→ Extract maximum value from every process

→ Minimize waste

→ Reinvest into the system

Brine fits right into this global transformation.

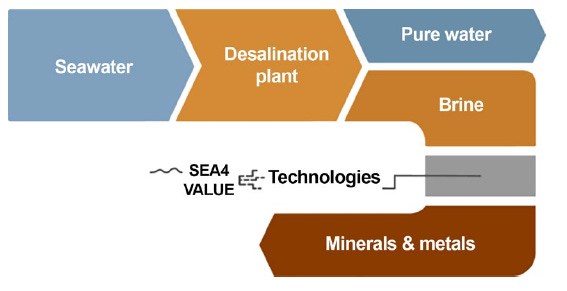

Brine is water with high salinity. It can be:

Naturally stored underground, like in the Lithium Triangle of South America, where it's extracted and processed to obtain lithium for batteries (and yes, that ties directly into EVs and the electrification trend).

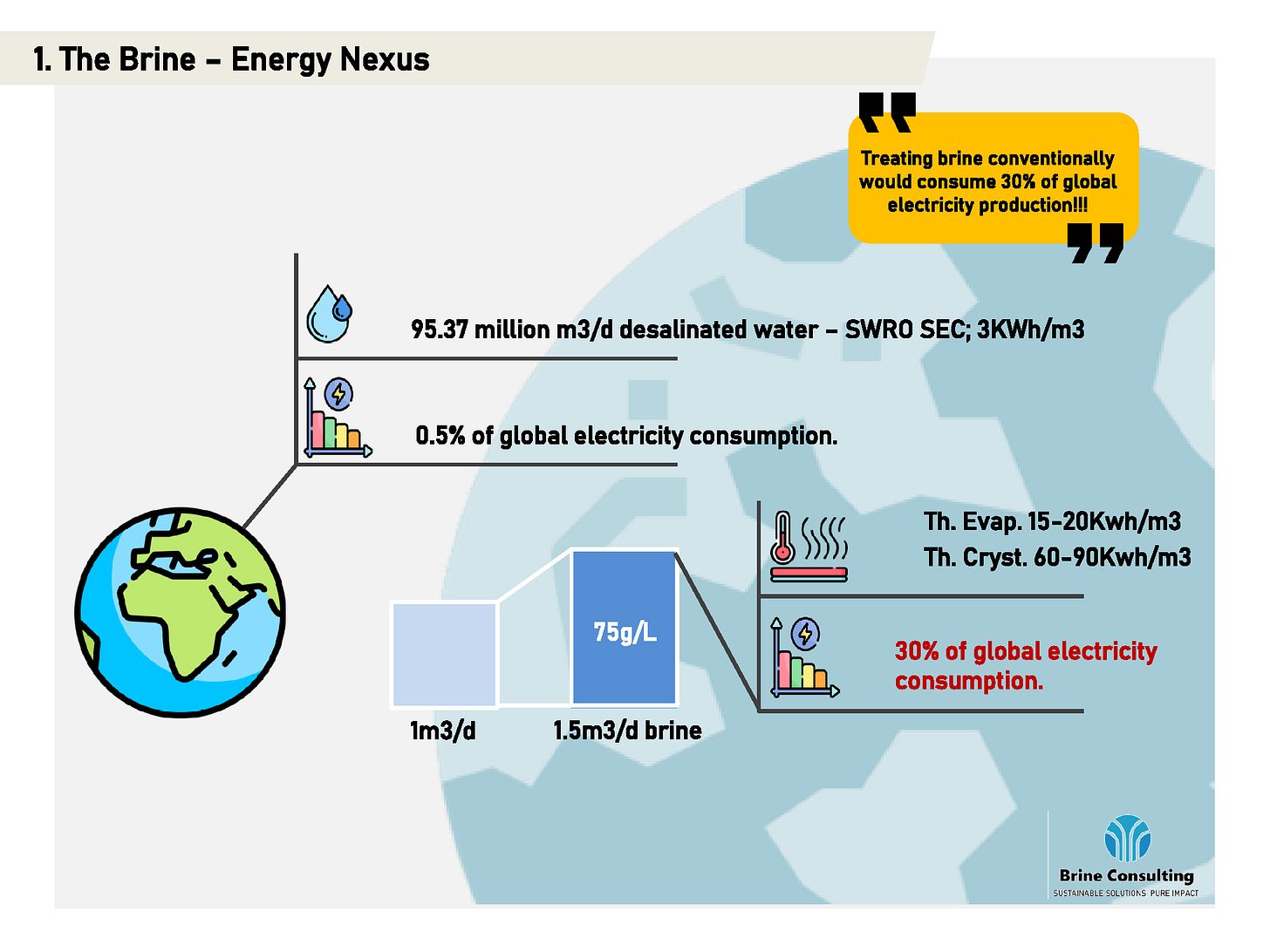

Or it can be the waste product of desalination plants, discharged back into the sea, millions of cubic meters every year.

While often viewed as useless or even harmful, brine contains valuable minerals and metals.

If we shift the mindset from "waste" to "resource," we unlock powerful opportunities.

Innovation doesn’t always show returns on day one. It needs:

Early adopters

Site trials

Market feedback

A few competitive players to scale, optimize, and reduce costs

What seems niche today may become industry standard in 5, 15, or 30 years. Brine valorisation is no different.

In our latest episode, we had the privilege of hosting Christos Charisiadis, a world-class water professional with decades of experience.

I need to confess he’s one of the most inspiring and respectful professionals I’ve met so far.

He now leads efforts at Brine Consulting, working to turn this emerging vision into real solutions.

We covered a lot, including:

The difference between “brine valorisation” vs. “brine mining”

(💡 Words matter, it’s not about extracting and leaving, but about recovering responsibly and sustainably.)The key minerals and metals found in brine, and which ones may have the strongest market potential

The current challenge of Zero Liquid Discharge (ZLD) regulations, and how a Medium Liquid Discharge (MLD) strategy might strike a more practical balance.

The 4 core steps of Brine Valorisation

We may consider creating a dedicated article for a deeper dive into this topic in the next season.

For now, keep this framework in mind to better understand the key stages of a brine treatment plant.

Pre-treatment

Concentration

Recovery

Purification

Each stage adds complexity—but also adds value.

One especially promising idea discussed in our episode:

Instead of installing full recovery systems in every desal plant, why not create centralized recovery hubs?

This approach could reduce costs, simplify logistics, and allow shared innovation.

The opportunity ahead

There are countless ways to create value.

And to do it right, we need people with vision and experience, like Christos.

We could have talked for hours. But this 1-hour episode is a strong starting point for anyone looking to understand:

The science and business behind brine valorisation

The regulatory landscape

The real-world opportunities just around the corner

Whether you're a policymaker, engineer, or investor, this episode is worth your time.

“What was once waste could be our next great resource. All it takes is vision, patience, and the right people in the room.”

Aqua Agitators

A quick reminder that Christos has hosted a series of great conversations on his Aqua Agitators channel, bringing together a lineup of top professionals in the water space.

I somehow found myself among them (still feels strange to say!), but honestly, the real gems are the other episodes.

My personal favorite? The one with Reinhard Hübner from Skion Water (I already mentioned last week), a truly insightful conversation.

Definitely worth a listen!

A case study from Veolia in India

The Grasim Nagda Project, a collaboration between Grasim Industries Limited (Aditya Birla Group) and industry partners, has set a new benchmark in sustainable manufacturing by implementing Zero Liquid Discharge (ZLD) in its Viscose Staple Fiber plant.

I had no idea of what’s viscose staple fiber was to be honest. I read that it is kind of cellulose.

Industrial water is really really complex, but probably the most fun. We already discussed about this with Marcos de la Monja in our episode at The Water MBA TV.

Located in the water-scarce region of Nagda, India, the project was driven by the urgent need for water conservation and regulatory compliance.

Achieving over 98% water recovery and recovering 40–50% of operational costs through byproduct extraction like sodium sulfate.

Global water awards

Recently, GWI awarded Blue Brine as the Water Technology Idol. Curious to learn more, I reached out to Christos, as I couldn’t find much information on the website.

I also spoke with Roy Zumwalt, who kindly connected me with Martin Hauschild, the speaker at the GWS event.

I’ve sent an email to explore the possibility of featuring this case study on our platform but have not received a response yet.

As Christos mentioned, MLD projects are showing great promise, highlighted by the recent recognition of one such initiative with the Industrial Project of the Year award.

It's increasingly clear that industrial water management is one of the main drivers behind the adoption of MLD and ZLD technologies, a point Christos emphasized in the episode.

The following is a summary of the awarded project, which is directly linked to dyeing processes and their significant environmental impact.

Dyeing processes are among the leading sources of water pollution, particularly in Asia, where much of the fast-fashion industry is concentrated.

These manufacturing hubs often operate with low costs and inadequate environmental standards, something we’re all connected to as consumers.

While many of these countries still face significant challenges, there is growing awareness and a shift toward protecting ecosystems and freshwater resources.

In this context, minimizing or eliminating dye discharge through advanced recovery solutions like Minimum Liquid Discharge (MLD) or Zero Liquid Discharge (ZLD) is incredibly valuable and impactful.

Reminder

July and August will be our preparation period (phone calls, reading, research, time for “brain valorisation…”, etc) for the upcoming season starting in September/October 2025.

During these 2 months, you’ll receive special articles covering some of our TOP episodes from 2024 that didn’t originally have dedicated write-ups.

Also, for next season, we’re opening the opportunity to include brief sponsorships at the beginning of our articles.

This helps us reinvest any revenue into new features, platform upgrades, and more learning opportunities for our growing community.

If you're interested or want more information → Be Our Sponsor