Making the Business Case for Water Reuse

Exploring the barriers, opportunities, and innovations shaping water reuse today and tomorrow.

Water reuse is rapidly moving from a niche topic to a central pillar of global water security, driven by growing pressures from climate variability and population needs.

The topic can be analyzed from many angles, so I wanted to hear from someone in the eye of the hurricane—someone who needs to understand and see the connections among all the pieces of the specific water reuse puzzle.

It is truly a privilege to learn with and from Veronika Zhiteneva and WaterLoop Solutions.

Open space for sponsors!

Curiously recorded the day of Waterloop Solutions first anniversary (happy bday!), a startup bridging research, regulation, and real-world implementation to make water reuse safe, practical, and widely accepted.

Why did she take this brave step of co-founding the company?

Because she saw a gap between research and real-life implementation (this sounds familiar from previous episodes…) of water reuse projects.

After her Master’s and PhD focused on water reuse, she realized that while the technology and knowledge existed, many projects struggled to actually get implemented.

She wanted to bridge the gap: helping projects get approved, monitored, and accepted—both by authorities and the public.

Essentially, Waterloop acts as a catalyst, ensuring that water reuse initiatives are practical, safe, and sustainable, rather than just theoretical.

She not only had the expertise but also the vision to make a real impact in water sustainability.

It takes real courage to step out of research and start a business (you’ll receive in your inbox another example very soon in 2026…!), a testament to the caliber of our guest. I wish her all the very best in this exciting adventure!

So let me repeat the quote, because I think it’s very important: we need to push and provide more focus on this specific point:

While the core technologies and scientific understandings largely exist, the challenge lies in successfully integrating these capabilities into real-life projects.

The necessity of systematic Risk Management

The increasing demand for water reuse stems not only from traditionally arid areas but also from countries like Germany, which now face regional water availability challenges.

This scarcity has prompted municipalities to reconsider using drinking water quality sources for non-potable needs like watering parks or cleaning streets.

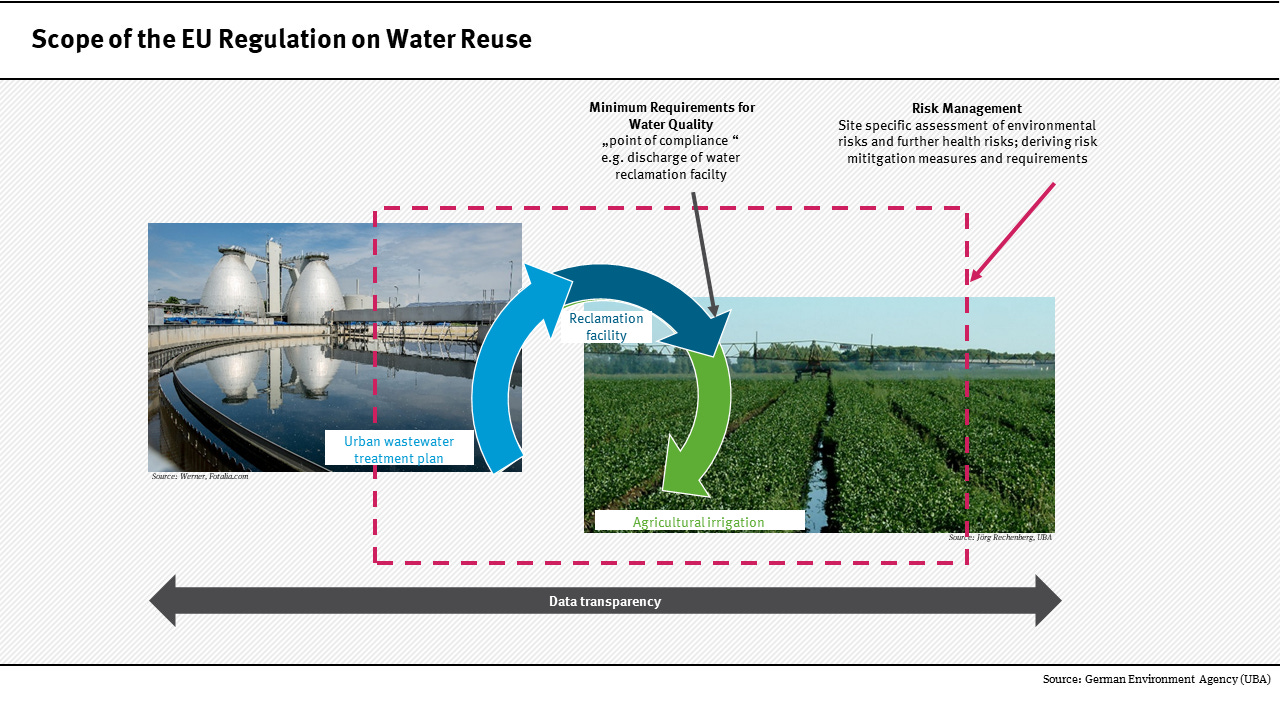

A cornerstone of safe water reuse—whether for agricultural, urban, or eventually potable uses—is systematic risk management.

The European Water Reuse Regulation (EU) 2020/741 mandates a comprehensive Risk Management Plan (RMP), consisting of 11 key elements (KRMs), to ensure safety for human and environmental health.

System Assessment: A detailed description of the entire water reuse system, from the wastewater entry point to the final use, identifying all involved actors and their responsibilities.

Hazard Identification: Identifying potential risks (pathogens and pollutants) and hazardous events (e.g., treatment failures).

Multiple Barriers: Using a series of preventive measures to control potential hazards. This multi-barrier approach ensures that if one component fails, others maintain the integrity of the water quality.

Veronika emphasized that this framework provides a necessary “recipe” for safety, ensuring transparency and consistent water quality through robust monitoring and control.

Complexity, bureaucracy, and public trust

Despite the established technical capabilities, implementing water reuse faces significant hurdles:

1. Regulatory Complexity and Permitting Challenges:

The detailed nature of modern regulation, particularly the lengthy technical guidance required for the EU RMP, can be overwhelming for those unfamiliar with the topic.

A major practical obstacle for clients is the often lengthy and challenging permitting process, which can take up to one and a half to two years.

This bureaucracy can sometimes lead users toward illegal water extraction simply because they cannot afford to wait for approval.

Overcoming this requires technical experts to perform capacity building and “distill down the scientific evidence” into simplified, manageable language for public authorities.

2. Economic Viability and Infrastructure Costs:

While conceptually sound, water reuse doesn’t always make immediate economic sense everywhere.

A key cost factor is the infrastructure required, particularly the expense and timeline associated with laying new distribution pipes.

These infrastructure costs can often be an even bigger question than the treatment itself.

Finding creative ways to form consortia and share costs between utilities, industry, and agriculture is necessary to finance these large capital investments.

3. Public Acceptance and the Stigma:

Public engagement is essential for the success of any water reuse scheme.

Opposition often arises from the lack of public understanding of the natural water cycle and the existence of unplanned (de facto) reuse, where treated wastewater effluent is discharged upstream and later used downstream for drinking water.

Furthermore, instinctive and emotional responses, amplified by stigmatizing language like “toilet to tap,” can quickly undermine logical reasoning and derail projects, as seen in the famous failure of the Toowoomba, Australia scheme (time ago).

Successful communication must focus on the resulting quality of the water, rather than its history or source.

The PFAS challenge

Veronika’s experience with PFAS (per- and polyfluoroalkyl substances) illustrates the complexity of emerging contaminants in the reuse sector.

PFAS is problematic because it is pervasive, found “in literally everything,” making source control highly difficult.

Veronika explained that in some municipal wastewater treatment plants, the concentration of PFAS can actually be higher in the effluent than in the influent !!!

Good job to the operator! Just kidding. This actually happens because certain PFAS break down into shorter-chain compounds during treatment.

These shorter-chain PFAS are more mobile and persistent, so instead of being removed, their overall measured concentration increases in the treated water.

In short: the treatment process can transform some PFAS into other forms, which may make the effluent PFAS concentration appear higher than the incoming water.

For facilities, the immediate steps involve identifying potential indirect dischargers (often industrial) and rigorously monitoring concentrations entering and leaving the plant.

Crucially, addressing PFAS cannot be isolated.

The modern water utility must adopt a holistic view, prioritizing and simultaneously addressing multiple regulatory pressures, including PFAS, the push toward energy neutrality required by the Urban Waste Water Treatment Directive, and the threat of yet-to-be-detected micro-pollutants.

Implementing advanced treatment processes necessary for planned reuse often provides the dual benefit of achieving high pathogen removal while addressing trace contaminants like PFAS.

This requires utilities to think creatively and look beyond the water sector, seeking knowledge and solutions from other industries to adapt their operational thinking.

Financial responsibility (who pays for reuse)

The general principle of financial planning in water reuse projects requires determining the sources of revenues and clarifying who will pay for what.

While the ongoing regulation and norms primarily place the obligation of source control on those discharging industrial waste, and mandate that costs and financing be addressed in project planning, they do not contain details on specific pharmaceutical taxes or fees charged to the pharmaceutical manufacturing industry (extended producer responsibility) in the sources provided, although there is a mention of the extended producer responsibility within the context of the new Urban Waste Water Treatment Directive.

It is a bit confusing for me to be honest, but it seems that current regulatory frameworks “ensure” that entities (including those handling pharmaceuticals like hospitals or pharmaceutical manufacturers) that discharge hazardous substances into the municipal system are subject to pre-treatment requirements, strict discharge limits, and monitoring.

These actions internalize the cost of managing complex waste to the discharger, which is essential because the complexity and cost of treating these compounds are major components of advanced water reuse schemes.

Think of it like pollution control at the source: rather than charging the pharmaceutical industry a flat fee for the wastewater reuse system as a whole, the regulations require them to manage and pre-treat their specific waste to reduce contamination before it even enters the municipal treatment process, effectively making them financially responsible for the hazards they introduce.

I’d probably need more time to bring a clear example about this, so I’ll add to my 2026 to-do tasks list!

Open questions for thought

To encourage a deeper conversation about the future of water reuse, I address these open questions:

Decentralizing Risk Management

Much guidance exists for large, centralized systems.

However, for regions relying on decentralized or very small wastewater treatment plants, how can we scale comprehensive, multi-barrier risk management frameworks effectively to ensure safety without imposing excessive financial and regulatory burdens?

Financing Sustainable Infrastructure

Given that the capital costs for infrastructure are often the biggest barrier to widespread reuse adoption, how can we revolutionize collective financing models to share costs sustainably among diverse stakeholders (municipalities, industrial users, agricultural associations) to ensure critical water distribution infrastructure keeps pace with water scarcity needs?

Germany under water stress, really?

Recently, I was talking to a friend about water reuse in Germany, mentioning that they face some challenges with water availability.

He actually laughed at me and said, “Are you crazy? Germany has water problems?”

Naturally, that was my first question too.

It seems unusual, right?

But Germany can face issues both in water quantity and quality, specially due to groundwater levels are falling in some areas, and precipitation has been critical during dry years (e.g., 2018, 2019, 2022).

Another curious example is the Rhine River, as Veronika explained.

What happened?

The river fell to very critical levels during these dry periods. This is significant because the Rhine is a major transportation route for millions of euros of goods, so low water levels have economic impacts.

The chemical industries (such as BASF and Bayer) and the steel industry (such as ThyssenKrupp), along with the shipping and logistics sector, were among the hardest hit by the drop in the Rhine River’s water levels, as boats could not deliver the raw material to those industries due to navigation issues.

Guidelines?

Save this to your favorite page, you now have a mix of the main guidelines that need to be followed up for this topic:

EU Water Reuse Regulation 2020/741 – Sets minimum requirements for safe water reuse across EU member states.

DWA M1200 Factsheets (DE/EU) – Technical guidance on water reuse practices and monitoring.

Federal Water Supply Ordinance (Germany, expected 2025) – National standards for reclaimed water use.

California Title 22 Recycled Water Regulations (USA) – Rules for recycled water use including indirect potable reuse.

California Direct Potable Reuse Regulations (USA) – Strict log removal and monitoring requirements for DPR.

Technical Guidance — Water Reuse Risk Management (Europe) – Focus on risk assessment, monitoring, and management for agricultural irrigation.

Australian Guidelines for Water Recycling (AUS) – National framework for planning and implementing water recycling projects.

WHO Potable Reuse Guidance – International standards and approaches for safe drinking water from reused water.

WHO Guidelines for Safe Use of Wastewater, Excreta, and Greywater (Vol. 4) – Comprehensive recommendations for health protection in water reuse.

Hey, great read as always. Water reuse is definitly critical. I'm always a bit skeptical about closing that research-to-implementation gap, but Waterloops vision sounds incredibly promising. Thanks for sharing!