Energy Recovery in desalination, what you really need to know.

The device that makes desalination a viable option.

I’ll be revisiting and repurposing top content from 2024, this time with context, commentary, and key takeaways.

Whether you’re catching up or rewatching, think of this as your curated highlight of the year that was.

If you’re serious about desalination, understanding Energy Recovery is non-negotiable.

I say this from experience, having coordinated three major engineering projects since 2016, I thought I had a solid knowledge.

But this episode proved me wrong… or better said, it opened my eyes.

Our guest Rolando Bosleman from Energy Recovery breaks it down in a way that truly clicked for me.

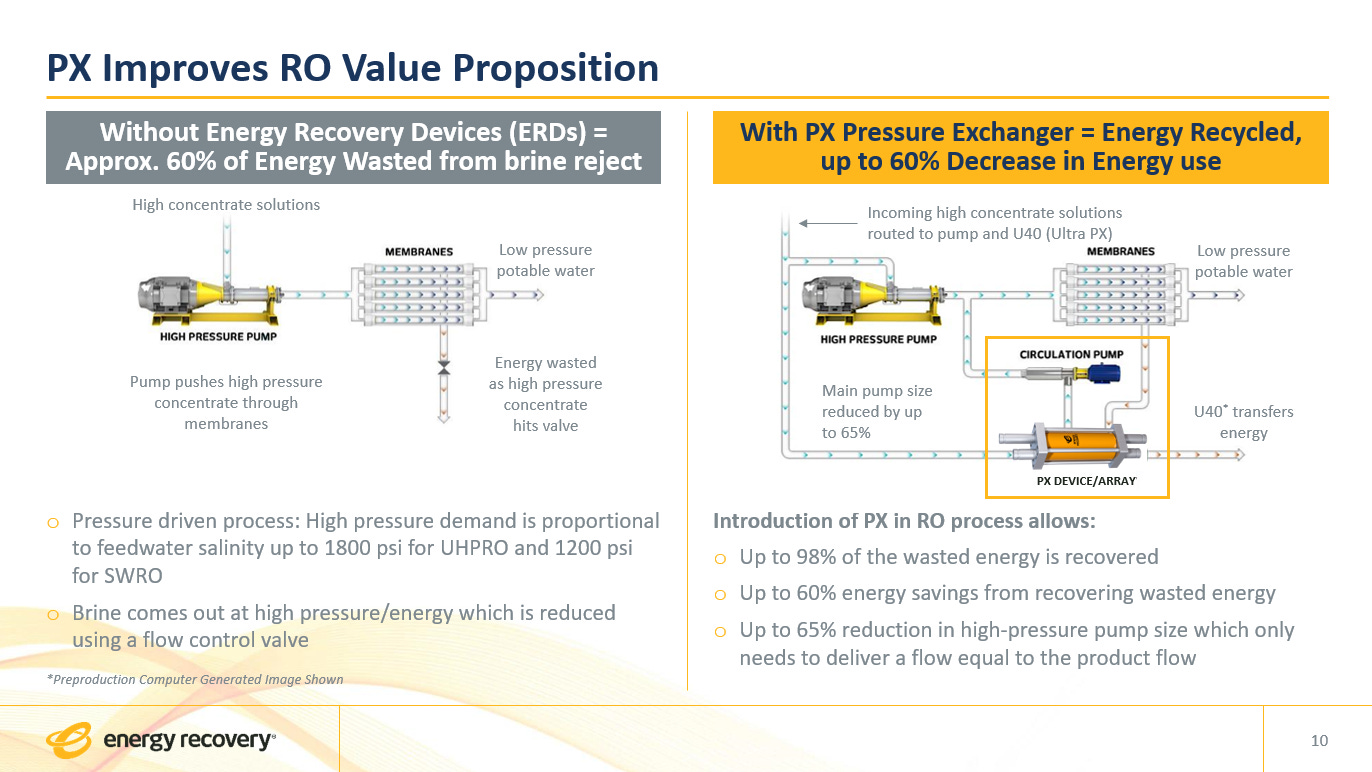

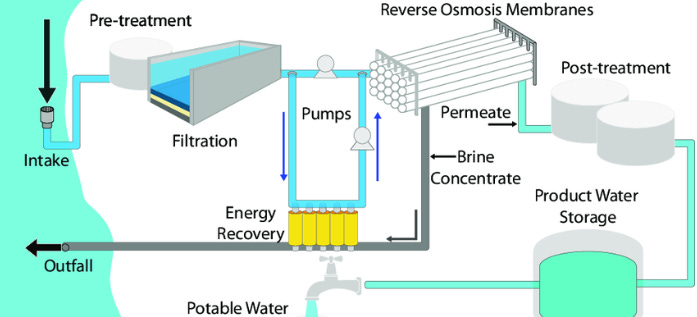

Especially the comparison between desalination systems with and without energy recovery, something so fundamental, yet rarely explained this clearly.

For example, back in 2005, the PX220 was installed in the Perth Desalination Plant, marking a leap in efficiency.

Fast forward to now, the PXQ400 is on the scene.

As you’ll see in the graph, we’re talking bigger scale, bigger efficiency.

And when you consider that up to 40–50% of a SWRO (Seawater Reverse Osmosis) plant's lifetime cost is tied to energy consumption, even the smallest gains in efficiency can mean millions saved, or better said, millions that can be invested elsewhere.

One thing I really appreciated was digging into the practical side: I asked Rolando Bosleman about the supposed “simplicity” of the energy recovery device, its near-zero maintenance, and what can actually go wrong.

We touched on biofouling, and that distinct noise you hear when a unit stalls, small signals with big implications.

I highly recommend watching this episode. You’ll get:

A crash course on desalination fundamentals.

A dive into the PXQ400 and its evolution.

A few sharp questions at the end that might save you from costly mistakes.

This one’s a must-watch.

The blessed dilemma for EPC & Developers

Here’s a small dilemma that illustrates why collaboration, partnerships, and long-term vision are so valuable.

Imagine you are bidding on a project where your objective is to achieve the lowest water tariff ($/m³) over 25 years of operation.

That tariff depends on both capital expenditure (Capex) and operational expenditure (Opex).

Now, the EPC contractor has two options:

Use the PX Q300, resulting in a total RO plant Capex of $100 million.

Use the PX Q400, which involves fewer units, a higher unit price, a smaller footprint, different piping configurations, and improved guaranteed energy consumption, resulting in a higher Capex, say $102 million. Less competitive at first sight.

It’s essential to lay all figures on the table.

The developer or utility must take a holistic view.

Since energy consumption is the main driver of Opex in desalinated water production, even small efficiency gains can justify a slightly higher Capex, especially when factoring in interest rates, debt servicing, and other proportional costs.

So, if two competitors present bids at $100 million and $102 million respectively, it is still necessary to assess the broader impact.

If both proposals claim the same guaranteed energy consumption, the one using the PX Q300 may still have room for improvement.

That’s why it is important to negotiate these aspects thoroughly during the tender stage, to reach a win-win scenario.

How important it is in real projects

How the energy recovery concept is approached in real projects?

Well this is a sneek into the content we’ll share in our Desalination MBA in 2026.

What are the criteria that determine the number of ERIs required in each train? How important is it to properly estimate the number of units?

One additional unit per train may cost between 40,000 and 70,000 USD (including all related items modifications, expenses and proportional costs), and if you have 10 trains, that means around 0.5 million USD of extra Capex.

How important are the velocity and configuration at the manifolds?

This is usually a heated discussion with owner engineers.

Biofouling remains one of the major challenges for plant operators, posing risks to maintenance, operational expenditure, and the overall performance of the facility.

It is especially critical for the proper functioning and lifespan of membranes.

Rolando shared valuable insights on how biofouling can be better managed, and highlighted that, in rare cases, it can also affect energy recovery devices.

While these units are designed to be virtually maintenance-free, severe biofouling may cause them to stop functioning and require disassembly.

This is why early detection and preventive strategies are essential (take a look at your pretreatment!).

The biggest RO Plant in the world

I had the opportunity to coordinate the engineering of the Taweelah IWP (Independent Water Project), with a capacity of 909,000 cubic meters per day, located in Abu Dhabi.

We secured an impressive contract valued at 23.5 million USD.

This purchase, just one out of more than one hundred that may be made within a project, is larger than many entire water projects around the world.

To put it into perspective, it means recycling hydraulic energy equivalent to over 900 gigawatt-hours annually, which corresponds to approximately 550,000 metric tons of carbon emissions.

A small anecdote, I worked on the tender competition as part of the tender team. My role was integrating the costs and fix an integrated vision of the project, so the proposal manager could handle big figures and strategies.

I remember being seated at a room at my former office with Juan Garcia Millan, opened an excel file, as we had to include a not to exceed figure for using energy consumption required for the commissioning works.

I was then realised the huge amount of energy this plant was requiring…

“ok we start turning-on one high-pressure pump and 1 rack for 2 weeks,…then another one,…then followign month,…then full system…then performance test 48 hours…finally the reliability test at 100% capacity…” figures rounding from 50 to 100 GWh, only for commissioning.

1 GWh = 1,000,000 kWh

100 GWh = 100 × 1,000,000 = 100,000,000 kWh

Now multiply by the cost per kWh:

100,000,000 kWh × $0.08 = $8,000,000

So 8 M$ only for commissioning this plant, before handed over to the operator.

It is insane, right?

Can you imagine this without using an energy recovery device?

The agreement validated The Water MBA

I want to express my deepest gratitude to Amy Davis and the Energy Recovery Legal and Marketing Department for placing their trust in our initiative back in October 2023.

I am well aware of the high level of professionalism this company demonstrates when handling projects. They pay close attention to terms, conditions, and contract negotiations.

So when I received a signed agreement from their side, I thought:

If Energy Recovery sees potential in this, even when all I had was an idea and a modest website, then this validates the business model. Let’s move forward :)

We’re opening the opportunity to include brief sponsorships at the beginning of our articles.

This helps us reinvest any revenue into new features, platform upgrades, and more learning opportunities for our growing community.

If you're interested or want more information → Be Our Sponsor

What an interesting read!! Thank you.

The industry already offers decentralised modular systems, ready to be deployed worlwide. For instance in Canary Island due to the volcano, a modular plant had to be sent to produxe potable water to local communities. Actually, next season I will feature a specific episode about these plug and play desalination plants, so stay tuned!