Discovering Ceramic Membranes

And right in the middle of it all, ceramics keep showing up, louder every time.

I’m finding an intersection between different inputs I’ve been receiving lately (described later) and in the middle I see more and more ceramic membranes.

So I brought in one of the fastest-growing companies in the market today, Cerafiltec, along with someone truly exceptional both professional and personally — Douglas Espin, whom I had the chance to meet in person just two weeks ago in Valencia.

Space reserved for future sponsors…more info here.

The Barrier: “Ceramics are expensive”

One of the most persistent issues faced when discussing ceramics with clients and engineers is the long-held belief that “Ceramics are expensive”

This doubt has been a key barrier for 15 years .

We must move the conversation beyond the initial capital expenditure (CAPEX) to focus on the total cost of ownership (TCO), which includes CAPEX plus OPEX.

As you may already know, many business models make this kind of lifetime analysis challenging — especially when the EPC and O&M are separate entities, and no single player oversees both.

The long-term financial case is clear: a ceramic membrane is a hard material that can come with 20-year warranty periods, offering double the typical lifespan of current polymeric modules.

We joke that the ceramic from your grandmother is still around, and these filtration plates, which only face suction and chemical processes, experience minimal mechanical wear.

Choosing based solely on the cheapest initial price means ignoring the profound long-term savings and robustness that ceramics provide.

That being said, lifetime-cost figures can vary widely depending on the assumptions used and the person running the numbers…

Wrestling with aggressive water quality

The water we treat today is becoming increasingly complex and “aggressive”.

I’m receiving this kind of input from time to time.

A little curiosity from the other day: about a month ago I visited my city’s drinking water treatment plant with the regional Young Water Professionals group.

We did an amazing tour — lab, control room, all spotless, everything looking calm and under control. It almost felt like nothing ever goes wrong.

But then I wandered away from the group and caught one of the lab technicians for a quick chat.

“Be honest with me,” I asked. “Any real issues with water quality lately?”

One of them let out this pffft sound and said, “You have no idea the days we have here…”

I looked around and told her, “Well, everything looks so peaceful.”

She just shook her head: “Believe me.”

So I pushed a bit further: “I mean, the water we drink today has to be much better than what my grandparents drank. Regulations are stricter, treatments are better… My grandpa lived to ninety with water that had no ozone, no activated carbon, nothing. So why worry so much now?”

And she looked at me and said: “Don’t forget that the raw water quality was much better back then. We’re receiving worse and worse water every year — in every parameter. It’s becoming more and more challenging to make it work.”

All I could say was: “Wow. I wasn’t expecting that.”

Ceramic membranes are uniquely suited to handle these mounting challenges, including:

High Loads: Plants frequently encounter high NTU (turbidity), sometimes reaching 1,000 NTU during periods like monsoons.

Persistent Algal Blooms: Algal blooms, which used to be seasonal, can now last for 12 months of the year. This is a hot topic nowadays in Australia, facing an historical algal bloom season (check this talk in one of my fav Pod). Also countries like Oman are really struggling with this more and more often.

Emerging Contaminants: New regulations demand robust removal of contaminants like PFAS, microplastics, pharmaceutical residues, heavy metals, and radioactive isotopes like radium and uranium. In a trial, ceramic systems successfully removed 99.9% of PFAS.

Mechanics: The advantage of suction

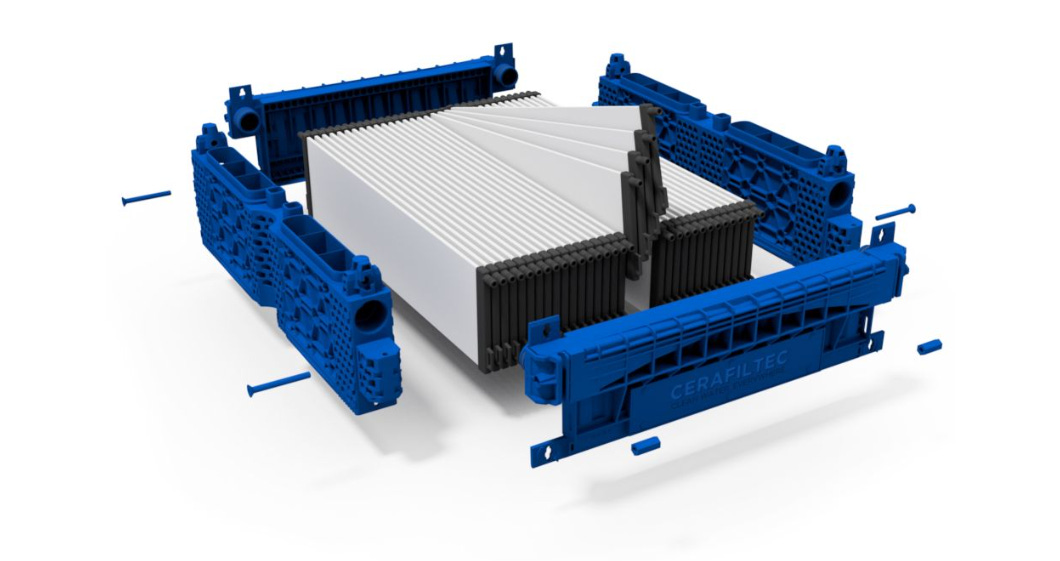

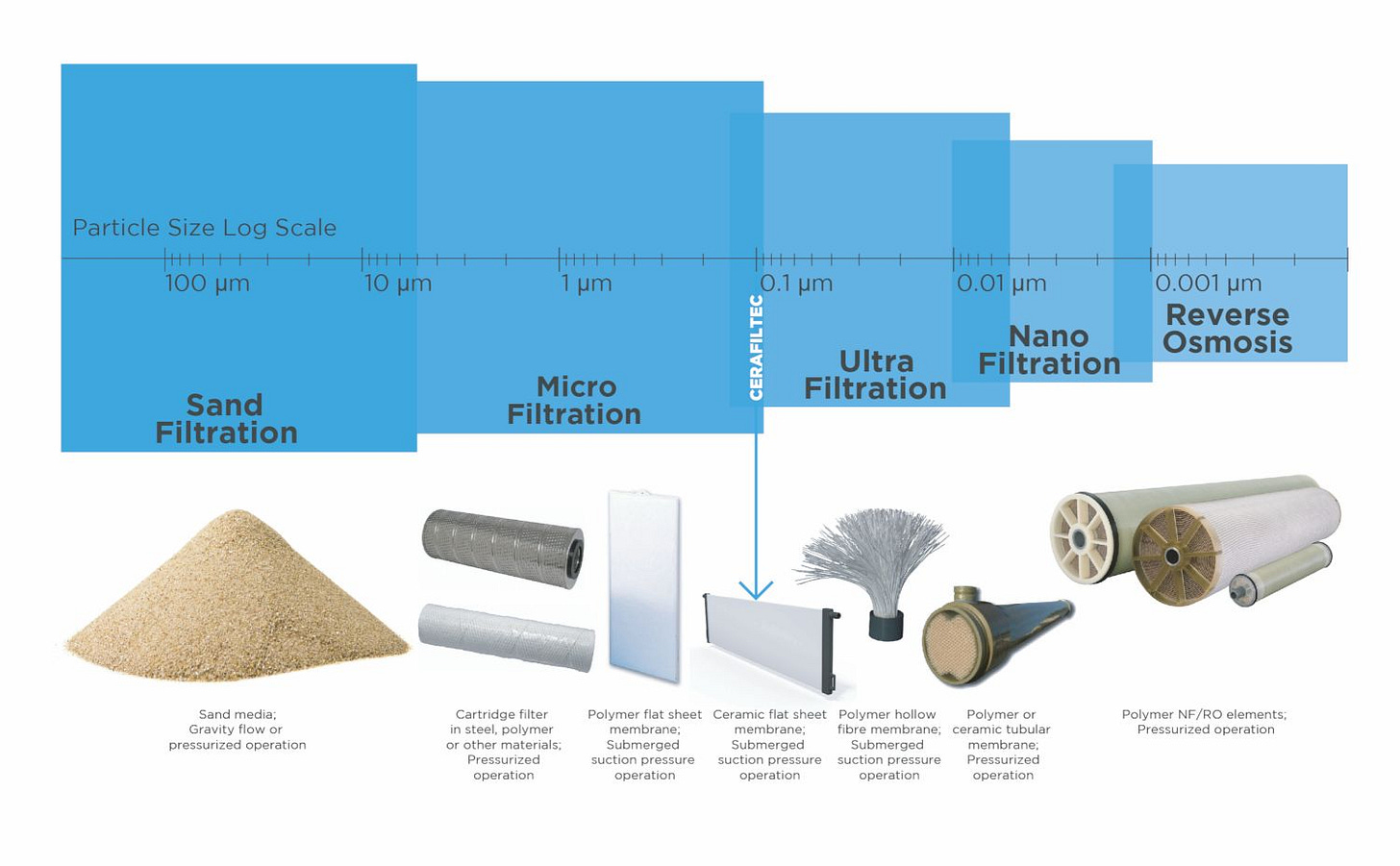

Ceramic membranes come in two types: tubular and flat membranes. Our focus on flat membranes employs an outside-to-inside flow using suction.

The module sits inside the dirty water tank, and water is sucked through the surface into the inner channels.

This operates at very low negative pressures (e.g., -100 to -300 millibars).

The suction approach offers a critical advantage over pressure-driven systems (like the inside-outside tubular type).

If you are sucking water, particles rest on the surface but are not squeezed deep into the membrane.

Douglas used the analogy of drinking pineapple juice with a straw: if it blocks, you stop sucking and blow a little to release the blockage

Conversely, when pushing water with pressure, mud is squeezed hard into the membrane surface, making it far more difficult to remove during backwash.

Ceramic supremacy: a summary of core advantages

The superior materials science and operational design of ceramic membranes address the fundamental weaknesses of conventional polymeric systems.

First, ceramic membranes demonstrate unparalleled durability and longevity.

As a hard material, they possess high mechanical strength, mitigating the issue of fiber breaks that plague polymeric systems and require frequent, labor-intensive repairs (pinning off).

Their robust nature allows them to offer a 20-year proven lifespan.

Second, they offer superior thermal and chemical stability.

They can operate effectively at high temperatures, up to 70 degrees C, and show less temperature effect when dealing with near-freezing water, unlike polymerics whose capacity can drop significantly in the cold.

Chemically, they can withstand working environments ranging from pH 2 to 12.

This resistance allows for aggressive pre-treatment steps, such as using ozonation, hard oxidation, or shock oxidation directly before the membrane, which is typically damaging to polymeric membranes.

Third, ceramic membranes deliver high operational efficiency.

They exhibit excellent antifouling properties (prepare your self for 2026 we’ll bring you 2 episodes about this topic really worth watching…) and can achieve high flux rates—often two to four times higher than polymeric membranes (e.g., 125 GFD ceramic compared to 38 GFD polymeric in one case study).

This high flux translates directly into needing fewer modules and skids to achieve the necessary capacity, leading to a substantial reduction in the required footprint of the plant.

Cleaning processes are optimized for recovery and safety.

The innovative method utilizes the capillary force of the membrane to suck chemicals into the pores for fast and effective cleaning, critically ensuring that no chemicals enter the filtrate side.

Furthermore, the system’s ability to handle contaminants like oil (being oleophobic, managing up to 100 ppm of oil) reduces operational stress, particularly in municipal wastewater applications.

Here a 3-minutes video to see how they really work:

Versatile applications: from desalination to difficult effluent

Ceramics are suitable for a vast range of environments, meaning they “could be” considered the standard solution in the future.

For industrial applications, such as metal, textile, oil and gas, or food and beverage, ceramics thrive under variable conditions.

For instance, a food and beverage client dealing with bacteria stress from constantly switching between sweet chocolate waste and different types of cat and dog food found that ceramics could withstand higher variation than their polymeric systems.

By combining flocculation and ultrafiltration into one step, plants can eliminate stages like DAF, sand filters, and microfilters, leading to a reduction in CO2, OPEX, energy, and chemical costs.

In desalination and municipal water, ceramics are proving revolutionary.

In desalination, using ceramics as pre-treatment protects the Reverse Osmosis (RO) system by securing an SDI less than 3.

This implementation allows for the removal of structures like DAF and pressure filters entirely, resulting in a huge reduction in civil works and plant footprint.

Personal Note: I’d like to dive deeper into the numbers. Most of the major issues in large desalination plants seem to stem from conventional pretreatment, so I suspect there’s something else holding back wider implementation of ceramic membranes.

New plants in the Middle East are still being specified by end users using conventional methods…

I’m about to start work on two or three new large-scale desalination plants in 2026. Believe me, the next couple of years would be so much easier if DAF and DMPFs weren’t part of my workflow :)

Additionally, ceramic membranes enable effective retrofitting; in one sand filter rehabilitation project for a 160 MLD plant, removing the sand and installing ceramics tripled the production while dramatically improving water quality (0.1 micron compared to 50 microns for sand).

The future, as Douglas believes, is defined by these hard materials.

As our source water becomes harder to treat and regulations concerning contaminants like PFAS become stricter, the robustness and efficiency of ceramic membranes will determine water security globally.

For more information, take a look at the video media available from Cerafiltec.

Why did I bring ceramic membranes to you?

During the last 10 years, I’ve received a few contacts from ceramic membrane suppliers in my inbox, asking for analysis.

As I was mainly dealing with large-scale desalination plants, where the RFPs and requirements are more or less defined by the end user, I didn’t have much reason to dive deeper into their priorities.

However, it was one of the topics I clearly understood had to form part of our water business puzzle.

It had been on the queue list for some time, but I decided to give it more priority after Paul O’Callaghan told us the following in his episode:

“I don’t want to be the last person... selling a PVDF membrane when PFAS compounds have been outlawed and everyone’s moved over to ceramics.”

So, if Paul — the CEO of a company clearly ahead of the curve in water technologies, commercialization, and market trends — is making such a clear statement, there must be something coming.

Paul used the shift from PVDF membranes to ceramics as a clear example of a technological evolution that CTOs must anticipate, driven by regulatory changes (like the outlawing of PFAS compounds), to ensure they do not miss out on new market opportunities.

PVDF’s uncertainty

A few weeks ago, a fellow member of our community, Salvador Prado, let me know that something is happening that could disrupt the market, in line with what Paul also highlighted.

The uncertainty facing PVDF, the polymer constituting an estimated 85% of all membrane bioreactors (MBRs) worldwide, stems from a regulatory proposal published by the European Chemicals Agency (ECHA) on August 20, 2025.

This proposal classifies PVDF as a PFAS “forever chemical” and includes it under a proposed restriction.

This regulatory action introduces a defined horizon for PVDF membranes and compels the global water industry to seek alternatives.

A critical challenge is the mismatch between the regulatory timeline and asset lifecycles.

Polymeric membranes typically have a 5-to-10-year lifespan.

If the PFAS restriction follows in a worst case scenario, maybe water filtration applications would only receive a 6.5-year derogation period, meaning a new PVDF installation today could be restricted or phased out before its first planned replacement cycle.

Even less severe restrictions create significant uncertainty, reducing PVDF demand and posing a material risk to operators.

Investing in the incumbent PVDF now carries the risk of a costly, forced retrofit within a decade.

This situation represents a contemporary regulatory crisis that industry experts believe will trigger a significant market shift, potentially accelerating the adoption of alternatives like ceramics twice as fast as typical value-driven adoption.

Ceramic membranes are exceptionally well-positioned to benefit from the PVDF uncertainty because they offer a future-proof, robust, and sustainable solution.

Do you have something could complement our learning?

After spending the past weeks digging deeper into ceramic membranes, I’ve been left with a mixed feeling.

On one hand, it’s obvious that they’re gaining more visibility and technical recognition.

On the other hand, they’re still not being widely implemented.

My impression, and I’m sure many of you share it, is that this is largely a matter of cost as Douglas mentioned.

Many of you either have direct experience with ceramic membranes or have even decided against using them in your projects.

If you have any comparative analysis, financial evaluations, lifecycle studies, or practical insights that could help us understand the real bottlenecks behind their limited adoption, I would genuinely appreciate it.

Anything you can share that adds context or helps us keep learning — and eventually deepening the research around ceramic membranes over the coming months and years — will be extremely valuable.

Water meets finance

This week, I published an article on LinkedIn.

At The Water MBA, we appreciate members who take the extra step to share their expertise with the community.

One of them, Vasilisa Gorbolskaya, senior analyst at Coho, shared an insightful perspective on the role of water in the corporate world today.

To be honest, I was not aware of this company, Coho, an ERM Group company (the largest global pure play sustainability consultancy), is a global climate adviser dedicated to helping clients navigate complexity on their climate journey.

Companies such as those operating data centers, which rely on credit to keep growing, are increasingly treating water as a strategic resource…you can read the smooth words below from Vantage.

Here’s the link to the article—about a 2-minute read.

A gift?

As we approach the corporate budgeting season, many of you are likely working on your 2026 plans — including training, development, and professional resources.

So here’s a gentle reminder: consider including The Water MBA in your training portfolio.

As you know, most of the content is free, like this sunday’s essay. Still, I encourage you to take two simple steps.

First, subscribe to our TV channel. It’s just €5 per month or €50 per year — a symbolic amount for any company — and its value will continue to grow steadily over the coming years.

Second, if you work in desalination, project management, or simply enjoy this type of in-depth writing, consider upgrading your membership. It’s also €5 per month, under €50 per year, and it gives you access to top-tier insights you won’t find anywhere else.

And if your company isn’t the right route — or you prefer something more personal — you can also gift a membership.

Ask for it as a Christmas present, or give it to someone you believe will benefit from it.

This is a great moment to set things up so that 2026 helps us move one step closer to our long-term vision.

Ultimately, all of this only works thanks to you.

So, truly, thank you.