The Screening System

Exploring the overlooked but vital world of water intake screening systems.

It is fascinating to learn how critical the first step is in any major industrial process that relies on water.

From my personal experience, engaging with clients and internal management often involves lengthy discussions trying to determine the best approach for water intake systems, a part of the plant that can often be overlooked but is undeniably key.

Without proper pre-treatment, there is no debris-free water, and consequently, the pumps cannot run, meaning the entire plant is effectively shut down.

This necessity holds true across various demanding environments, including desalination plants and power plants (those require large flows specifically for cooling systems).

In this edition, we follow the water’s path from the deep sea to the plant, starting with the very first system it meets onshore.

In this essay, I share what I think it is worth being aware of:

Why and how a simple failure at the screening stage can shut down an entire desalination or power plant.

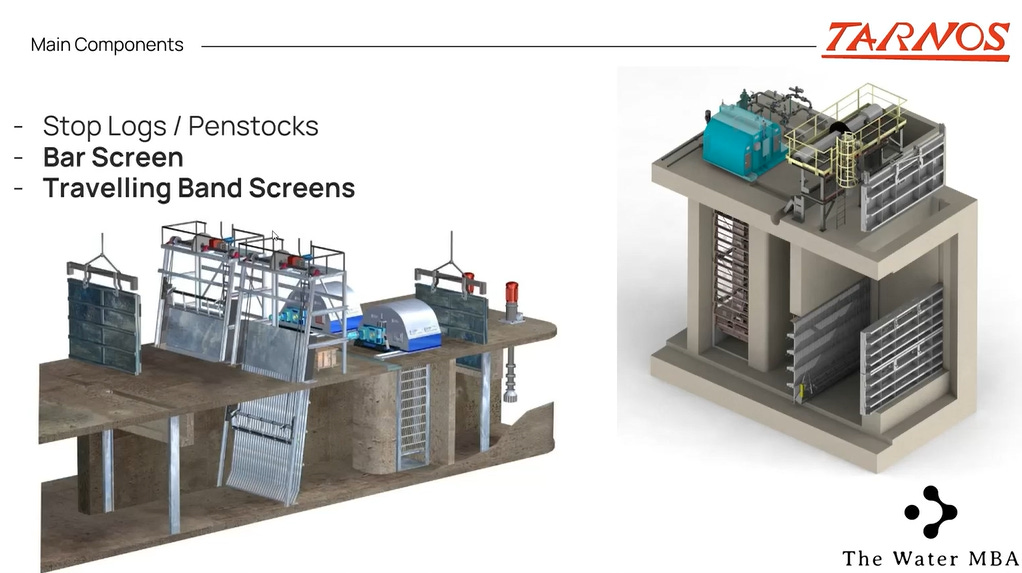

What a screening system really does and how coarse and fine screening work together to protect pumps and downstream processes.

How bar screens and trash rakes operate, including the differences between designs, redundancy needs, and maintenance strategies.

How traveling band screens (TBS) function as the fine filtration stage — from mesh size selection to washing systems, chain types, and material choices.

The pros and cons of through-flow, dual-flow, and center-flow screen designs (this is usually a debate among consultants and contractors) and why “carryover” is one of the most common design pitfalls.

How to balance hydraulic performance, with recommended velocities and head losses that ensure laminar flow and avoid cavitation.

Best practices for installation and maintenance, including the role of stop logs, embedments, and self-supporting structures.

How fish protection systems are designed (be careful, if your client requests this system, it is not a minor aspect) and why they often conflict with high-pressure cleaning or chlorination systems.

Typical operational and design mistakes, from washing system failures and worn chains to missing stop logs or wrong flow data assumptions.

How to interpret head loss stages, and what they tell you about the health and operation of your screening equipment.