Common causes of Control Systems failures

How to manage DCS reducing risks and improving integration.

I wanted this conversation because the control system & automation is often treated as the final “plug-in” at the end of a project, a minor detail to be handled once the concrete is dry.

However, the reality is that the control system is the nervous system of any plant.

If it is not integrated correctly from the start, the entire project suffers from delays and technical friction.

This essay highlight how we can prevent the most common causes of project failure and unnecessary stress.

What you’ll learn (maybe) in this essay:

Why involving the automation provider during the early phase leads to a more robust and coherent overall project design.

How early definition of communication protocols and engineering practices helps reduce rework, integration issues, and long-term costs.

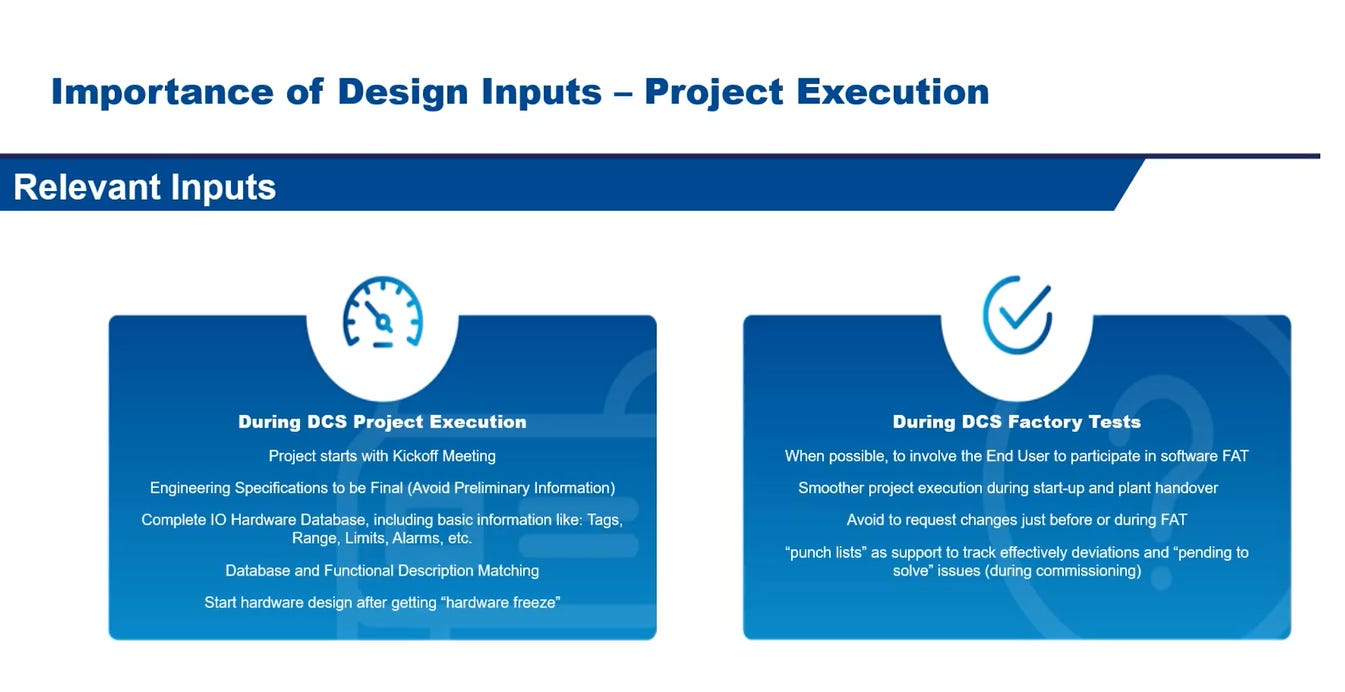

Why a proper kickoff meeting, clear responsibilities, and disciplined coordination are essential from the very beginning of a project.

How prioritizing engineering quality over artificial schedule pressure (do not laugh if you read this please…) improves execution, testing, and commissioning outcomes.

How these principles played out in a real project at Taweelah (900,000 m³/day), where early DCS engagement—despite an immature design and multiple variations—ultimately led to a smoother FAT, easier site execution, and a positive overall outcome.