The Cartridge Filters

Protect your membranes, optimize your costs: Cartridge filter strategies explained.

The CF system’s primary function is critical for protecting downstream equipment, especially by preventing premature fouling of the RO membranes, blocking metallic particles that could damage ceramic components in energy recovery devices (PX units), and protecting pumps.

Welcome to another edition of Desalination MBA Insights

This is one of my fav publications so far. I’ve been slowly attacking the topic from different angles, and I tried to compile what I think I would put on the table to any professional involved in desalination.

Here reflections are shared to think together about:

Design Trade-offs: Flow, Size, and Cost

Learn how to use the magic rate Filtration flow per 10” equivalent (m³/h).

What are the main “concerns” from Owners / Engineers when approaching this system? These are my notes. Whenever a new project starts, I review them to avoid repeating past mistakes and to be prepared when the Owner raises the usual comments.

Do you want to know how to commission this system? Just follow our easy guideline.

And how can you estimate or even guarantee the cartridge replacement rate? Well… that’s the tricky part…

Metaphorical Insight

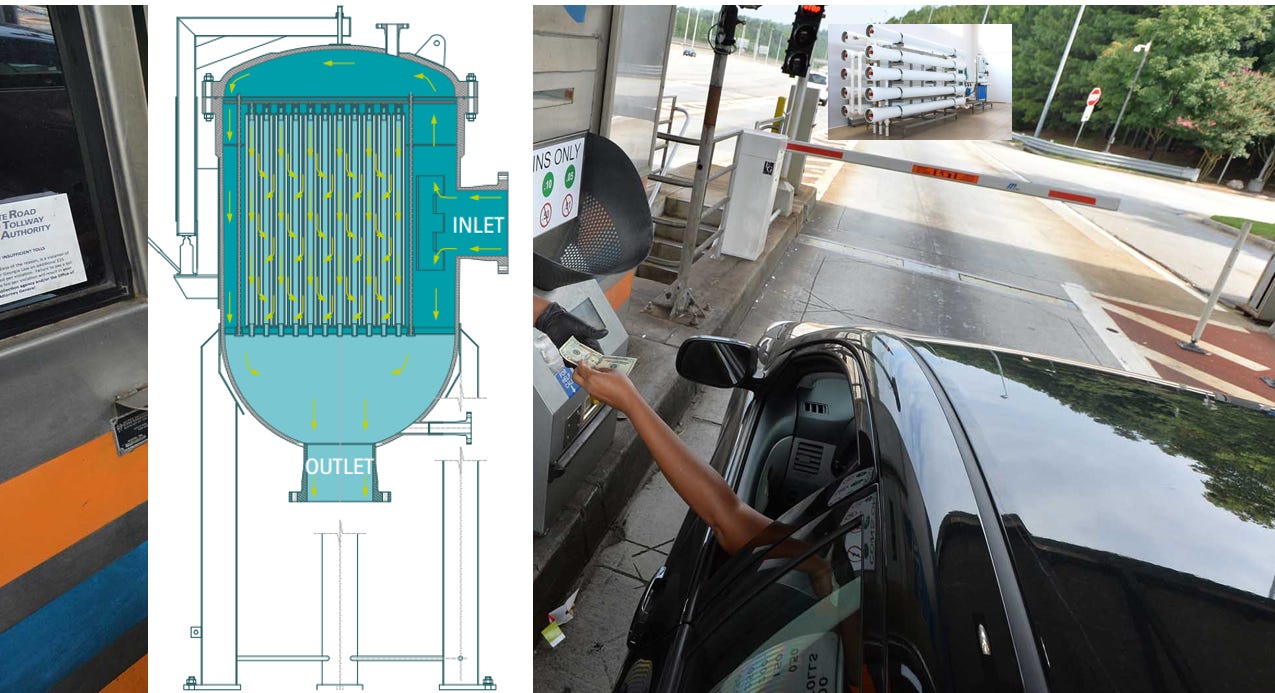

Think of the cartridge filter system as the tollbooth operator on the highway to the expensive RO membranes.

If the operator (filter) is properly sized and equipped (using the right cartridge type and material), traffic (water flow) moves efficiently, protecting the high-speed lane (RO membranes).

If you under-staff or under-equip the tollbooth to save a minor upfront cost, you create immediate bottlenecks (high Delta P, energy loss) and risk catastrophic accidents down the line (membrane failure due to particle breakthrough).

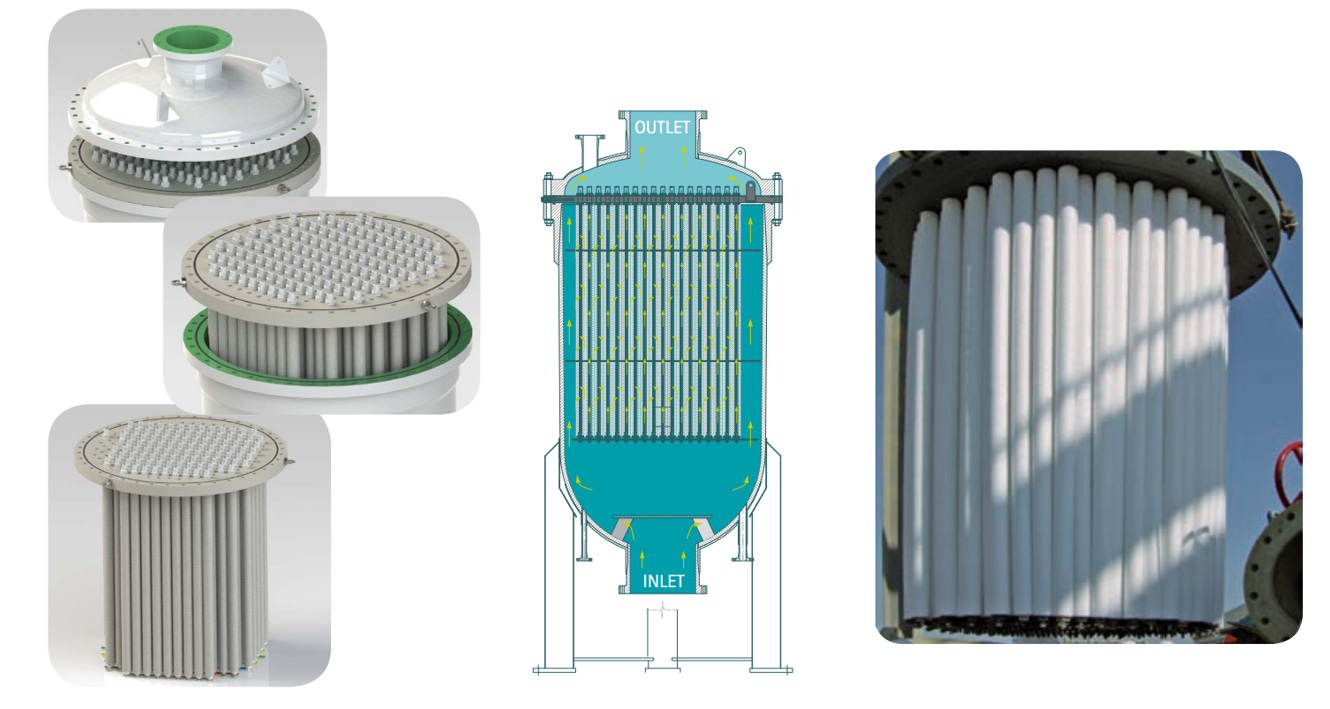

I’ll use support documentation provided by Fluytec, as you may know, one of the most reputable suppliers of this system worldwide.

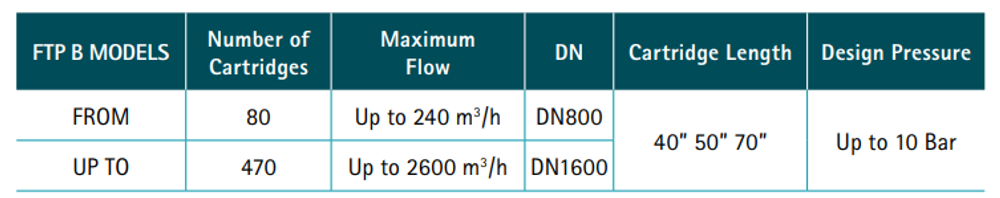

Below you can see a typical range where the cartridge filter design ‘game’ can be played.

However, we can go above this range, especially in very large-scale plants.

Still, in most cases (to be checked case by case), it’s not worthwhile to install very large filters (in the order of 3,000–3,600 m³/h per unit) due to logistical constraints and because you end up installing higher standby capacity anyway.