Size & Quality Matters: XXL HDPE Pipes

Scaling up desalination with confidence, HDPE solutions for the world’s most demanding intake and outfall systems. Go big or go home.

Our focus in this episode is on desalination plants, thousands of them around the globe, each with their own intake and outfall systems.

From these installations, I'm confident that over 70–80% rely on HDPE, a material trusted for its performance and durability.

Desalination plants have been scaling up significantly over the past 10–15 years.

A DN900 pipe is one thing, but when you're talking about diameters of up to 3500 mm, that's a whole new level.

Utilities, developers, and operators all understand that the lifetime of the installation matters, the fewer headaches, the better.

And when it comes to long-term confidence, reliability, and robustness, solid wall HDPE pipes are simply unbeatable.

We have the privilege of speaking with the manufacturer offering the largest diameter capacity in solid wall HDPE, Agru and their impressive XXL pipes.

But what happens when things get really big?

No worries—Markus and his team handle projects up to 3500 mm.

And it’s not just about the pipes.

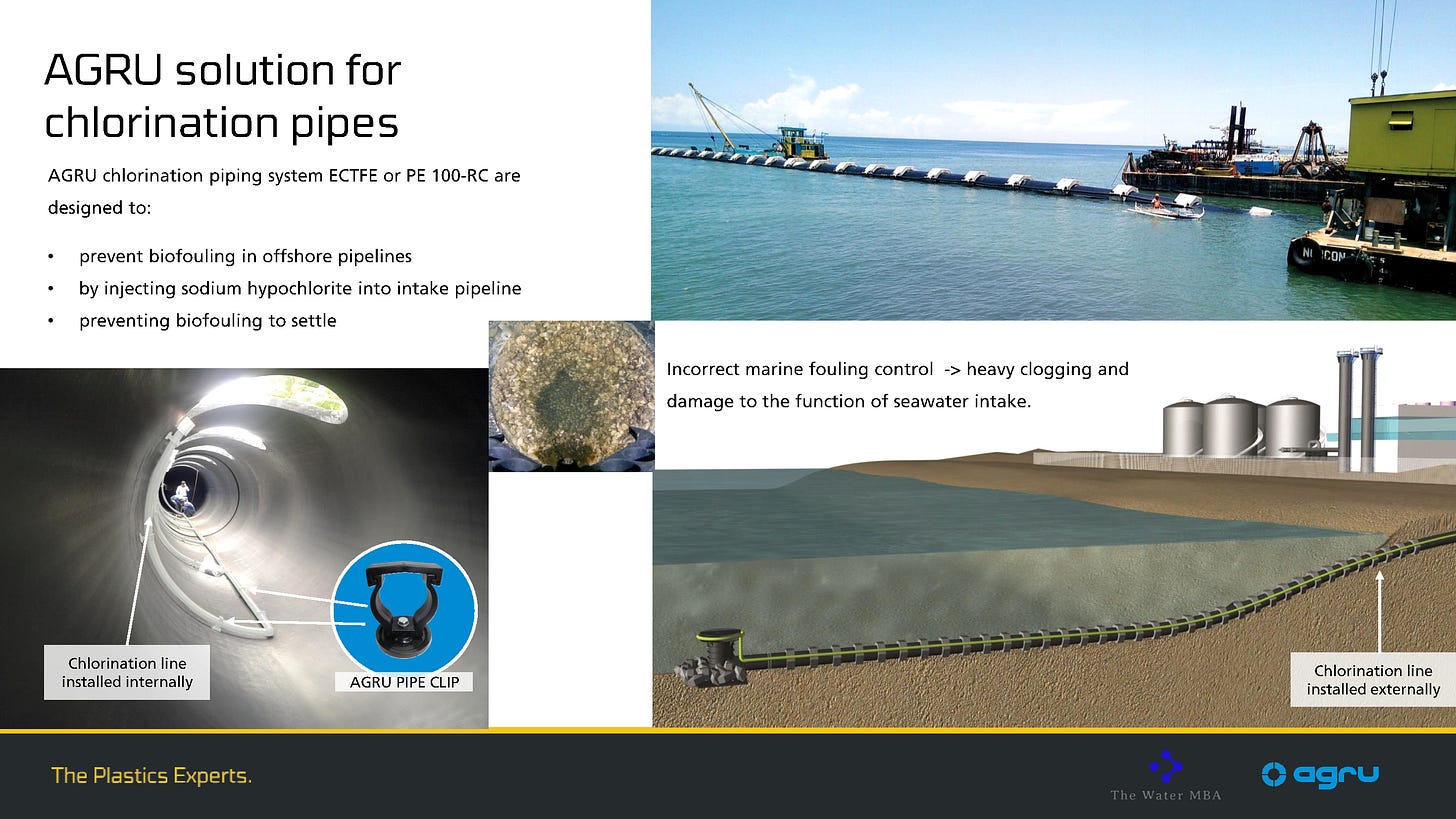

It’s the full system: special fittings, chlorination lines, diffusers, puddle flanges... everything around it.

Then comes the logistical challenge—how do you transport such massive pipes to the site?

Well, you’ve got options: you can go with loose 12-meter lengths, or, even more impressively, deliver a 600-meter pipe floating right in front of your site.

It’s unbelievable.

A breath of fresh air for site management—avoiding on-site welding, reducing laydown areas, cutting down on labor-intensive work.

Game-changer.

This episode is also part of our Intake & Outfall MBA course, where we share practical knowledge and lessons learned, the stuff you really need to keep in mind, because these same challenges come up again and again across projects.

Huge thanks to Markus Ebster, and also to Catalina Iglesias, they’ve been incredibly supportive of our community.

It’s clear just from watching the trailer we prepared together a few months back.

Go Big or Go Home

Speaking of big pipes, let’s talk about big things.

It’s hard to believe, but The Water MBA started almost two years ago.

After months of research, trial and error, we made it clear from the start: our methods will evolve, but our mission will always stay the same.

We’re constantly growing, adapting, and improving.

What began as a simple podcast has now transformed into a TV platform, with content set to increase exponentially in the near future.

This is a long-term journey, and our community continues to grow every day.

I’m not here to create something that’s just like everything else in the market. That’s why I’ve mapped out a bold roadmap leading up to 2030, packed with crazy ideas.

Here’s a sneak peek: I’m tentatively planning to host our first “major” in-person event in June 2026, in Seville, Spain.

I’ll keep you all updated on that as things progress!

Remember, life is too short and too precious to live just for the dreams of others.

So, go out there, do what you love, and as we always say: go big or go home!

Intake & Outfall MBA

In our ongoing video-on-demand course, remember—you can join anytime.

We’re currently in Stage 3, in which I shared the Operating System I apply every time I need to face a new project opportunity, so I can ensure the best decision taking process based on the data and analysis I get.

And I truly believe that by the end of 2025, the outcome will be something remarkable.

But honestly, more than the content itself, the real value lies in the connections we're building.

This course is a space for like-minded professionals to share, ask, and learn together.

We all face challenges in our daily work, and I keep an active dialogue with participants to adapt, troubleshoot, and evolve the course based on real-world needs.

The goal is to create a small but lasting community in this niche—a trusted circle where we can support each other as peers.

And just to give you an idea: professionals from companies like Nareva, ACWA Power, Strabag, Agru, IWAC, Dolsan Engineering, and AEC are already engaging with the content, taking notes, and using the knowledge to boost their work.

They’re not here by chance.

If they see value, maybe you will too.

Example from Part III:

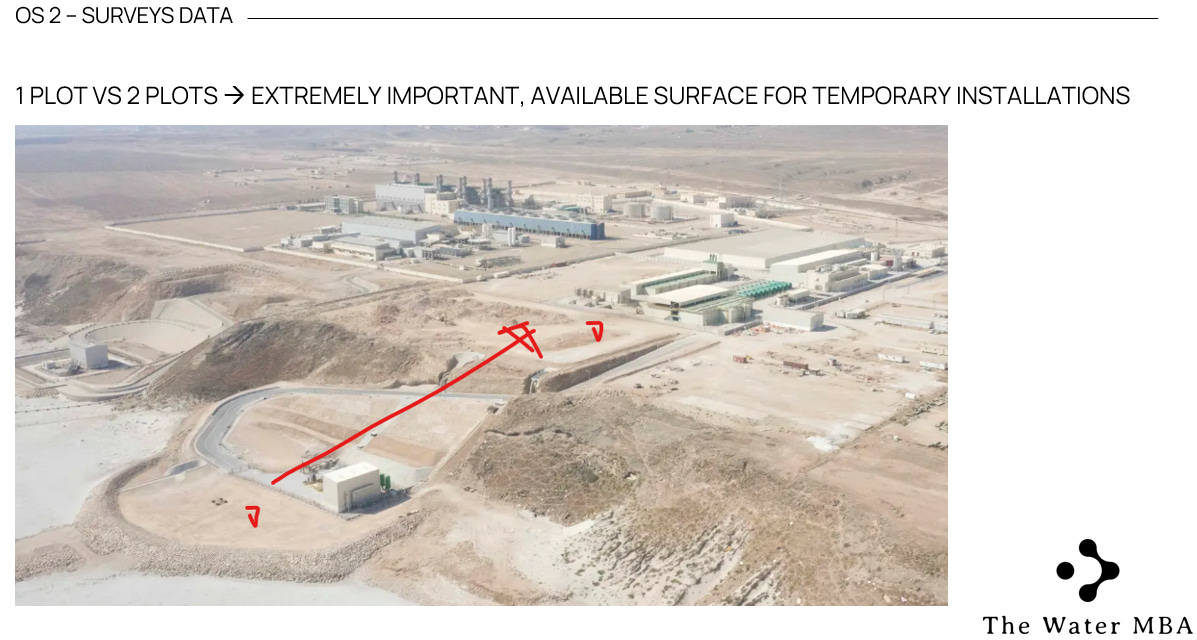

A common discussion in seawater desalination projects is whether to implement the Seawater Intake Chamber on the same plot as the rest of the SWRO (Seawater Reverse Osmosis) Plant, or on a separate site—especially in locations with complex topography or where there is a significant distance between the shoreline and the plant.

Another key consideration is the execution of the intake and outfall structures in the wave zone—the nearshore area where wave action is strongest and marine works are most challenging.

Take a look at the beautiful image below showing a temporary breakwater, which is constructed to enable safe operation of onshore equipment in the sea, minimizing the impact of wave action during construction.